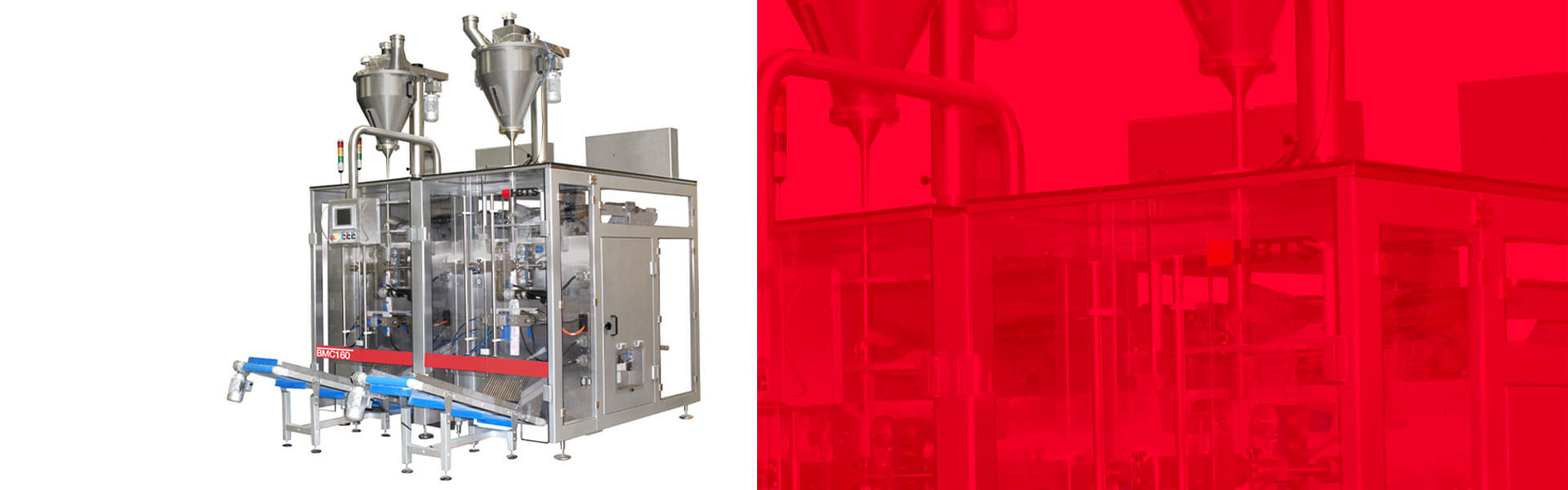

The BM series of intermittent and continuous motion vertical baggers, by HBTS, are representing the state of the art in the industry ideally suited for the packaging of bulk and free flowing products of all kind.

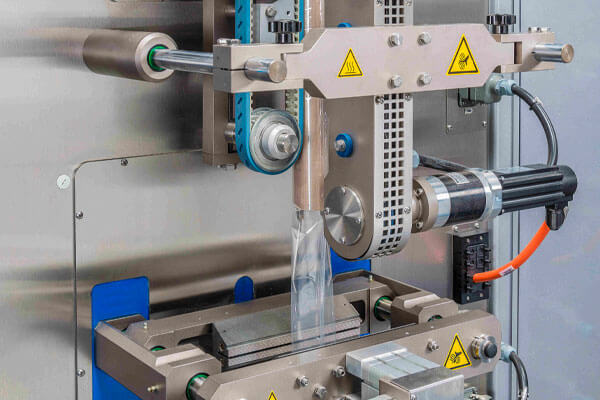

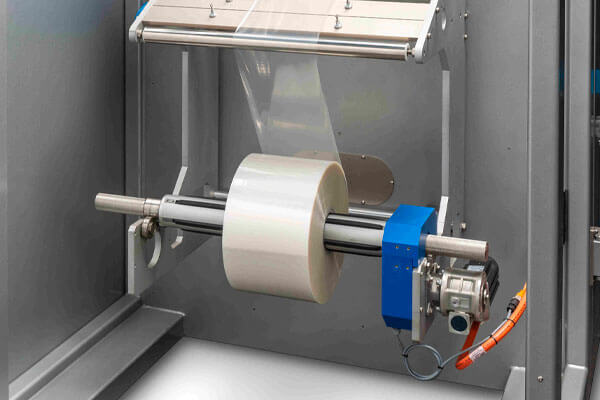

Suitable for almost all mono and laminated packaging material of different thicknesses can be also equipped with different sealing types like heat sealing, PE material impulse welding or ultrasonic sealing.

Strong welded open frame hygienic design construction on levelling elements these compact continuous motion VFFS servo machines are delivering maximum output ensuring a very high machine efficiency whilst producing perfect bag’s quality.

Built to last, this series is designed for low maintenance and for consistent 24/7 operations high performances year after year.

The machine can operate, according to the application, with a variety of products dosing systems and can be extensively customized in order to meet Customer’s specific requirements. The BM VFFS is available in 2 web widths with max bag’s width of 160 or 280mm.

This series is designed for highest flexibility in bags shape such as pillow and pillow chain pack, gusseted, block bottom and quad seals both with add-ons tooling.

Standard features include a large on board HMI for touch operations design and incorporates enabling the smooth adjustment of all operator inputs that are important for the packaging process: sealing time, sealing force, bag length and set output.

BM Series – Vertical Packaging

Solutions for the packaging of bulk products

This technology is suitable for packaging

- Biscuits

- Chocolate

- Miscellaneous

Contact us

Request more information about the product now

Other related technologies

Technology and Reliability

Solid expertise accrued in many years of successful challenging projects worldwide and the continuous striving for innovative, reliable solutions with the utmost care for details and our focus on easy to run and maintain systems are allowing HBTS to implement environmentally friendly technical solutions aiming to the best possible OEE and great ROI for our Customers.

Customization

In HBTS we understand very well the value of the flexibility and of space constraints therefore our solutions are designed to meet the required production volumes and to fit to the best in the available areas. Each solution takes in due consideration the potential future expansions and needs of a quick evolving market. We shall always be able to work out the best possible proposals for your needs.

Tailor made designing

Tailor made designed packaging systems is what we offer to our Customer’s base to meet even the most complex tasks. Each project step, from initial concept, to designing, to parts manufacturing, software development, construction, testing and final commissioning is taken care internally to secure full system’s compliance monitoring and future aftersales support year after year.