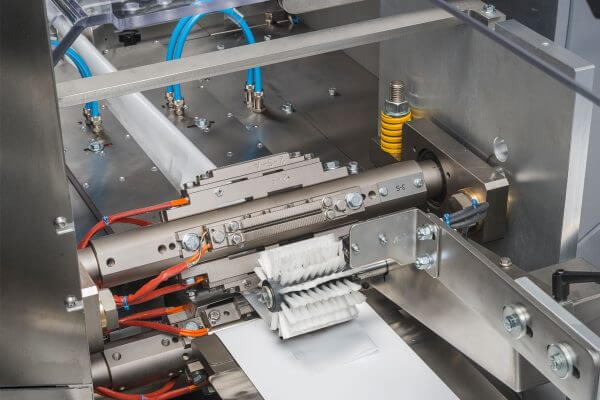

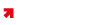

The MP Series is the servo driven flow wrappers range by HBTS are specifically designed for automatic packaging systems integration and are available in a variety of film unwinding capacity ranging from mid, high and extreme packaging requirements. Following to the “machines for systems” approach each and every MP model can be executed for mirrored layouts set ups and are pricing inclusive of the indispensable features such as double reel holder with automatic film splicing, motorized film unwinding, suitable film reel braking systems and much more. The MP range includes also special purposes machines incorporating specific infeed elements for products on edge flow wrapping and wafer’s blocks family packs applications. The MP series flow wrappers are based upon the latest motion technologies by Schneider Electric PacDrive 3 or Rockwell Automation Allen Bradley equivalent.

MP Series – Flow wrappers

For heat or cold sealing at high speed

This technology is suitable for packaging

- Biscuits

- Chocolate

- Baked goods

- Miscellaneous

Discover the details

Contact us

Request more information about the product now

Other related technologies

Technology and Reliability

Solid expertise accrued in many years of successful challenging projects worldwide and the continuous striving for innovative, reliable solutions with the utmost care for details and our focus on easy to run and maintain systems are allowing HBTS to implement environmentally friendly technical solutions aiming to the best possible OEE and great ROI for our Customers.

Customization

In HBTS we understand very well the value of the flexibility and of space constraints therefore our solutions are designed to meet the required production volumes and to fit to the best in the available areas. Each solution takes in due consideration the potential future expansions and needs of a quick evolving market. We shall always be able to work out the best possible proposals for your needs.

Tailor made designing

Tailor made designed packaging systems is what we offer to our Customer’s base to meet even the most complex tasks. Each project step, from initial concept, to designing, to parts manufacturing, software development, construction, testing and final commissioning is taken care internally to secure full system’s compliance monitoring and future aftersales support year after year.